INCA® HOT silencer created for heavy-duty use | Philosophy and strategy

The Silencer INCA® HOT stands for a A new dimension in soundproofing technologywhich is our most robust model in terms of material selection, manufacturing process and construction. This High-performance silencer was specially developed for demanding users who do not want to compromise on quality, safety and efficiency.

Philosophy and strategy behind the INCA® HOT

The strategy and philosophy of the INCA® HOT silencer is based on the vision of creating the perfect product for the needs of users who are exposed to high loads and demanding conditions.

Our development department has made a conscious decision to use only the best materials and technologies in order to exceed expectations in terms of durability, lightness and longevity.

The approach behind the INCA® HOT is based on precision and uncompromising material quality. The Choice of 100% Titanium 64 Grade 23 as material emphasises this claim: titanium is not only extremely light, but also offers exceptional strength and corrosion resistance.

The combination of state-of-the-art 3D printing technologies and a monolithic construction method enables maximum stability without weld seams or other weak points that could impair the structure.

100% Titanium 64 Grade 23 - the material of choice

The INCA® HOT consists entirely of a titanium alloy. Titanium is one of the most valuable and durable metals used in aerospace and medical technology. It has an exceptionally high strength and weighs almost half as much as steel.

The use of this material is a significant strategic advantage as it offers both corrosion resistance and durability and gives the silencer an enormous lightness.

Compared to aluminium, titanium is more stable at high temperatures and is therefore ideal for use in silencers.

Stability is maintained even during long, intensive periods of use. The use of titanium 64 grade 23 ensures a Significant increase in service life and a Maximum durability guaranteed, even under extreme conditions.

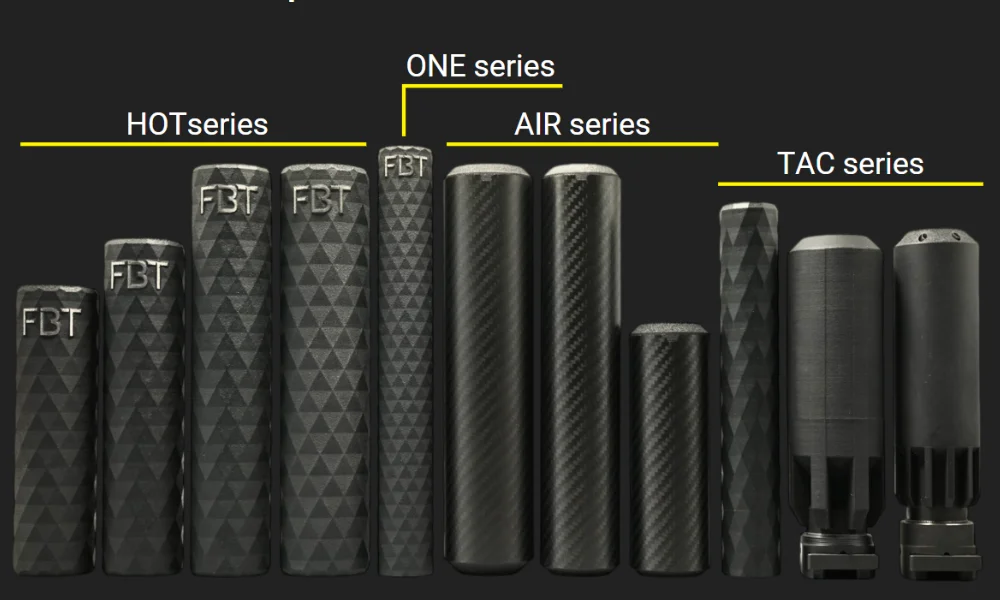

The INCA series

Precise 3D printing technology and monolithic construction

To meet the requirements for strength, durability and reliable damping performance, the INCA® HOT is manufactured using a 3D printing process.

The additive manufacturing method enables high component strength with low weight. The silencer is constructed in one piece using laser sintering, which results in a uniform, monolithic structure.

Thanks to the monolithic construction, the INCA® HOT has no weld seams or jointswhich could form potential weak points.

This design ensures maximum stability and safety, as the risk of material fatigue and breakage is minimised. This process enables us to create a product that sets new standards in terms of precision and durability.

Summary: The future of soundproofing technology

The INCA® HOT is an impressive example of state-of-the-art silencer technology.

The INCA® HOT sets new standards in the industry thanks to the combination of 3D-printed titanium 64 Grade 23, a precise monolithic design and a simple structure.

The extremely low weight and the possibility of use up to Calibre .50 BMG leave hardly anything to be desired.

Thanks to its high safety standards and superior durability, the INCA® HOT is the first choice for professional users who value efficiency, comfort and reliability.

The INCA® HOT silencer shows how product design, choice of materials and manufacturing technology interact, to create a product that is perfectly tailored to the needs of its users - for a powerful and durable application that is prepared for the challenges of today and tomorrow.