INCA HOT 79Ti silencer for long range weapons | 3D print titanium silencer for strong calibres up to 50 Browning (50 BMG) | AT and DE customers ONLY

€ 1.700,00 (€ 1.416,67 excl. VAT)

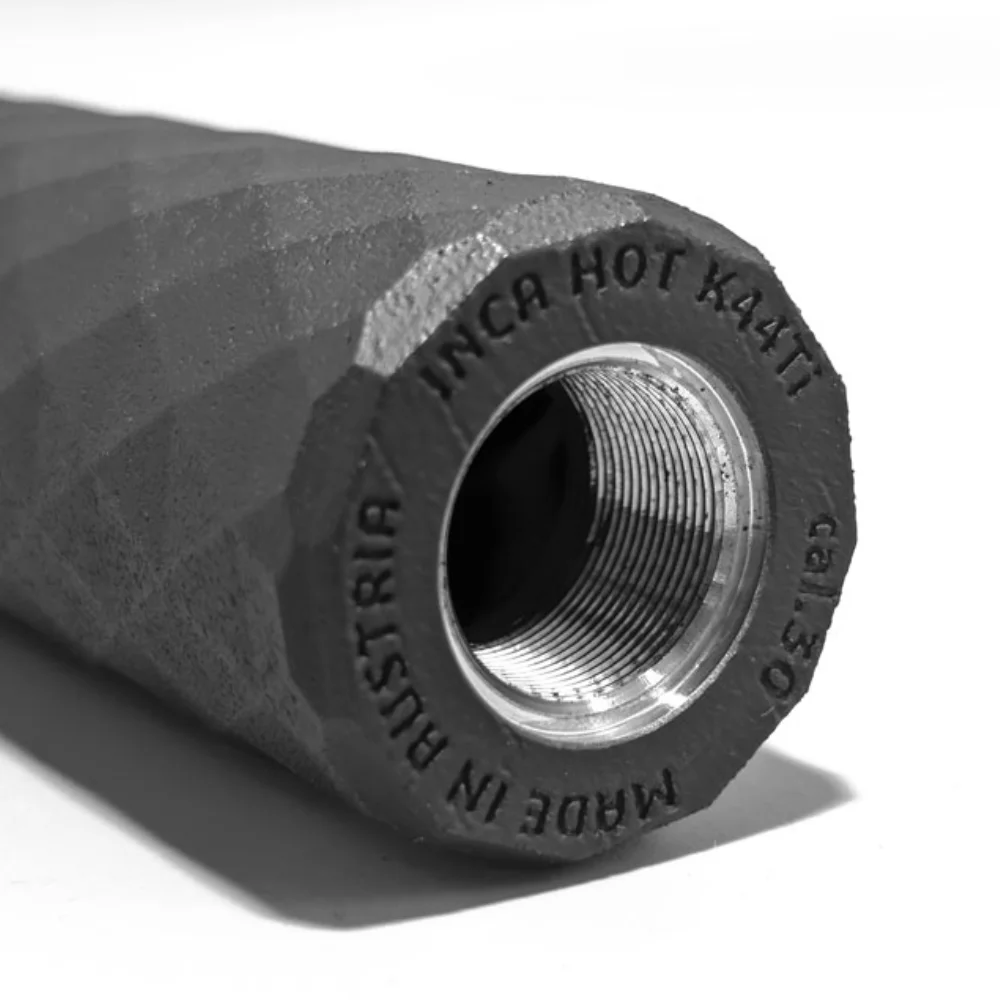

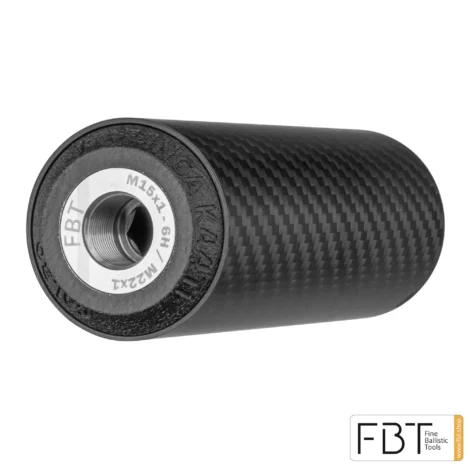

With M28x1.5 connection thread for Steyr HS-50 or other long range rifles. Other threads / adapters on request.

... or to put it another way: MORE Performance, MORE Resilience, LESS Weight with your INCA HOT silencer!

Austria Customers: Due to the legal situation, collection directly from us or from the local gunsmith is possible - see selection field!

Germany Customers: Due to the legal situation, collection from DE importer or delivery by DE importer - see selection field!

The sale will only take place after the owner's licence has been checked!

Delivery time: 2-5 days

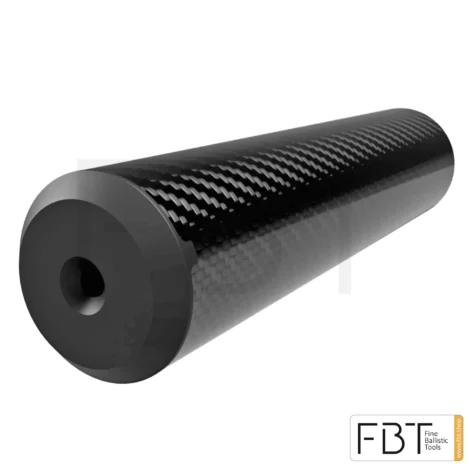

Silencer INCA HOT 79Ti UP TO CALIBRE 50 BROWNING | 100% TITAN SILENCER FOR GUNS | MONOLITHIC 3D PRESSURE TYPE | M28x1.5 CONNECTION THREAD

The INCA® HOT silencer stands for a new dimension in soundproofing technology, which in material selection, manufacturing processes and design is unrivalled.

The HOT high-performance silencer has been specially developed for demanding users who No compromises in matters Quality, safety and efficiency would like to enter into.

The titanium material used for the 3D printing of this silencer is the ductile Titanium Grade 23 (a titanium alloy with aluminium and vanadium) is used

In order to meet the requirements for precise, uniform and reliable damping performance, the INCA® HOT Suppressor manufactured using the 3D printing process.

This additive manufacturing method enables unrivalled precision and density. Each layer of the silencer is produced layer by layer from 100% Titanium to create a uniform, monolithic structure.

Thanks to the monolithic construction is available with the INCA® HOT No weld seams or jointswhich could serve as potential weak points.

The unique design ensures maximum stability and safety, as the risk of material fatigue and breakage is minimised. This process enables us to achieve a Heavy-duty silencer product that sets new standards in precision and durability.

No calibre can overtax the HOT series. Equipped with an M28x1.5 thread, it can be screwed directly onto the gun barrel.

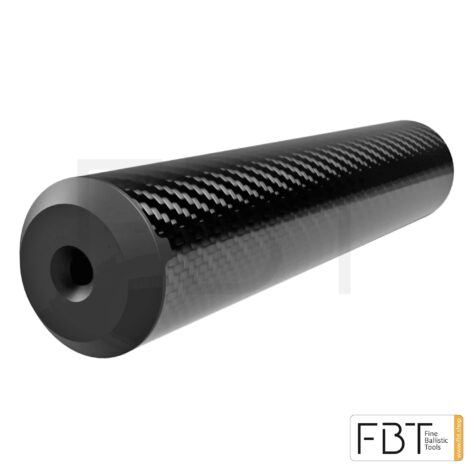

Lightweight silencer - a great relief for the user

A key feature of the INCA® HOT silencer is its low weight.

Thanks to the use of titanium and 3D printing technology, the weapon silencer can be manufactured extremely light without sacrificing stability.

This makes the INCA® HOT an ideal choice for situations in which Equipment worn for long periods of time or must be used continuously in extreme situations.

Lightweight equipment is a decisive factor for comfort and efficiency, especially on long missions.

The INCA® HOT guarantees a high Minimised weight greater freedom of movement and less fatigue for the user, which is particularly important for intensive operations offers a clear advantage.

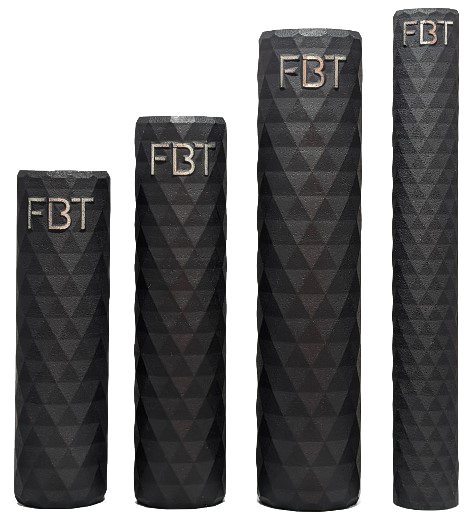

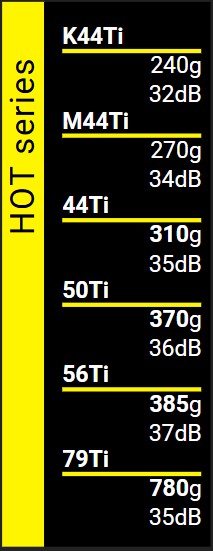

| Designation Silencer | Weight | Diameter | Length | Length from mouth | Damping performance* |

| INCA HOT K44Ti | 240g | 44 mm | 155 mm | 140 mm | 32 dB |

| INCA HOT M44Ti | 270g | 44 mm | 180 mm | 145 mm | 34 dB |

| INCA HOT 44Ti | 310g | 44 mm | 220 mm | 140 mm | 35 dB |

| INCA HOT 50Ti | 370g | 50 mm | 220 mm | 140 mm | 36 dB |

| INCA HOT 56Ti | 385g | 56 mm | 220 mm | 140 mm | 37 dB |

| INCA HOT 79Ti (up to 50BMG) | 780g | 79 mm | 220 mm | 205 mm | 35 dB |

* Measured at the ear of the shooter at a distance of 5 cm

Overview HOT SERIES

The INCA HOT Silencer innovation - Construction made of 3D printed, high-strength titanium with special surface structure

- No lateral forces on the damper thanks to guide ring adapted to the barrel

- Cleaning free

- Safe & precise

- Overpressure and splinter protection with low impact point displacement

- Efficient & light

- Best weight/performance ratio without being too top-heavy

- Narrow contour with minimal restriction of the field of vision

- Easily interchangeable adapters

Maximum titanium strength - for all calibres up to .50 BMG

Suitable for all Magnum cartridges

Principles of action of silencers in firearms: Scientific consideration and limitations

Silencers (suppressors) for firearms are based on the targeted manipulation of physical processes in order to reduce the sound pressure of the Muzzle blast to reduce the risk. From a scientific point of view, they combine thermodynamic, acoustic and aerodynamic principlesto fulfil their function. Nevertheless, their efficiency and mode of action are limited, as some physical phenomena cannot be fully controlled.1. pressure reduction and gas management

A main factor in the muzzle blast is the Pressure difference between the hot, compressed powder gases and the ambient air. Silencers delay the release of these gases by directing them into several expansion chambers.According to the general gas equation p⋅V=n⋅R⋅T (pressure, volume, number of particles, gas constant, temperature), the increase in volume leads to a decrease in pressure.Nevertheless, the sound pressure can only be reduced to a certain point, as the gases have to escape into the environment at some point.

2. thermal effects and energy conversion

The in the silencer materials used (there are big differences here) absorb heat energy of the expanding gases, which further reduces the temperature and thus the pressure.Theoretically, the sound intensity could be drastically reduced by perfect material design.However, there are limits, as even the efficient materials can only absorb limited amounts of heat and heat up with repeated use, which reduces their effectiveness.

3. sound wave control through reflection and interference

The chamber structure inside the silencer forces sound waves to reflect and refract several times. This causes destructive interference that reduces the overall sound. However, not all frequency ranges can be insulated equally efficiently. Low-frequency components (muffled noises) are more difficult to eliminate than high-frequency ones, which is a limitation of the technology.4. limits for supersonic ammunition

A fundamental limit of silencers is the handling of supersonic ammunition.At velocities above 343 m/s (speed of sound in air) a sonic boom (sonic boom)which is independent of the powder gas effects. Silencers can minimise this Do not eliminate the bangas it is physically caused by the projectile itself. To circumvent this, often Subsonic ammunition which, however, reduces the range and energy of the projectile.

5 Efficiency limits and legal restrictions

Even the best silencers can Bang of a gun cannot be completely eliminated. Studies show that the Noise reduction is often between 20 and 40 dBwhich makes the bang quieter, but not inaudible. These limits are also set by the physical properties of sound and the necessary projectile energy. In addition Legal requirements in many countries the construction and utilisation of such devices.Conclusion

From a scientific perspective, silencers are an impressive example of the application of physical principles to reduce noise. Nevertheless, their effect limited by thermodynamic laws, sound propagation mechanisms and the unavoidable dynamics of supersonic speeds. They can significantly reduce noise, but not completely eliminate it, and require optimised design to maximise their efficiencyScope of delivery FBT silencer INCA

1 pc. sound absorber INCA HOT 79Ti

| Weight | 0,8 kg |

|---|---|

| Brand | |

| Country of origin | Austria |

| Material | Titanium |

| Product type | Silencer |

SD Size Calibre

| Calibre | 408 Chey Tac, 416 Barret, 50 Browning |

|---|

Only logged in customers who have purchased this product may leave a review.

You may also like…

Accessories

Related products

INCA HOT series

INCA HOT series

INCA HOT series

Reviews

There are no reviews yet