Blog, Performance Centre

Takeover of VEREX TACTICAL | Weapon refinement - Individualisation - Customizing

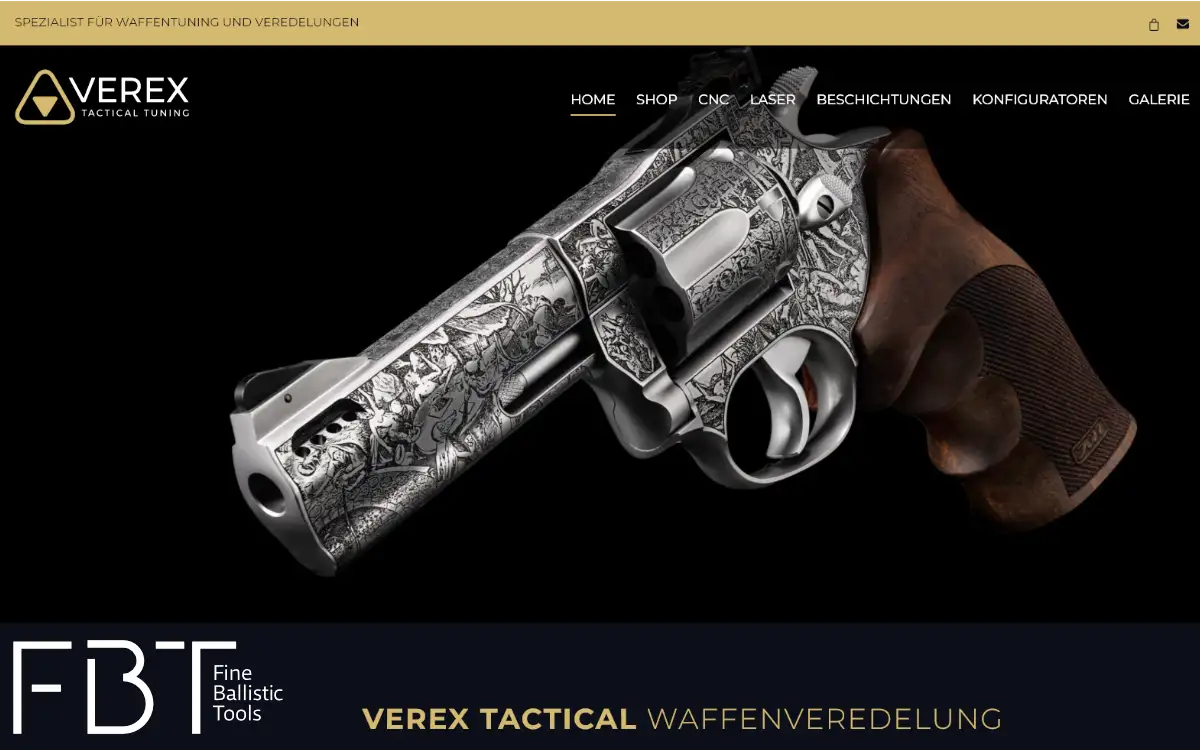

VEREX TACTICAL | HIGH END CUSTOMISING AND CERAKOTE COATINGS FOR FIREARMS

A few weeks ago, after extensive discussions and deliberations, we took over Verex Tactical and now combine all core competences under one roof.

Important strategic decisions for even better product optimisation always make sense - don't they?

From the most advanced weapon construction to the individualised weapon refinement everything is now customised, refined or converted under one FBT roof.

Immediate measure: The handles of our UNIC carbon shafts are Cerakote coated for optimum grip.

VEREX TACTICAL core competences

The scope of services of VEREX TACTICAL includes

- Slide cuts (skeletonisation)

- Cerakote, PVD, DLC coating

- Red Dot milling

- Laser engraving

- Handle machining

- Various accessories

Extract from the Gallery | Customisations from VEREX TACTICAL

An extremely interesting opportunity to GLOCK pistol individualised with Cerakote, the Cerakote GLOCK CERAKOTE configurator.

Cerakote weapon coatings, engravings and sight conversions of weapons are handled by Verex Tactical according to your individual wishes and ideas.

No matter whether you de facto weapon tuning (front serrations, Red Dot milling, etc.), sophisticated Weapons restorations or noble Engravings with 24 carat gold plating We are here to realise your ideas and visions to your complete satisfaction.

CERAKOTE coating as weapons corrosion protection

Not only for Sport shooters and gun collectorsbut especially for hunters who want to Hunting weapon in hard use Cerakote coating is the ideal solution to protect weapons from corrosion and surface damage.

The coating is particularly suitable for Replacement of bronzing or similar and gives your weapon a new look at the same time.

Cerakote is a coating specially developed in the USA for weapons, which is available in many colour combinations.

In addition to the desired visual enhancement, the gun is given a surface that protects against all environmental influences and the Service life of the weapon used for hunting.

Video: Comparison of different corrosion protection coatings in an extreme endurance test

How does the Cerakote coating essentially work?

After a degreasing acetone bath in the sandblasting cabin, the dismantled weapon parts are cleaned of old bluing or even flash rust and coated with a wafer-thin Cerakote layer in the colours of your choice recoated. This Durable ceramic coating from the USA obtains its final strength by firing for two hours at 120 °C in the special firing chamber.

In addition to the best corrosion protection, Cerakote offers also gives your weapon a distinctive look and increases its value. From elegantly sophisticated to post-apocalyptic - we design your weapon entirely according to your wishes.